RV Roof coating is the most common type of material used in all types of RVs found today. RV Roof coating is the RV’s roof main line of defense against all the extrusive elements. There are two main types of liquid roofing coatings and they are either EPDM, or Ethylene Propylene Diene Monomer, and TPO, or Thermal Polyolefin. Both of these coatings are synthetic rubber compound and each is having its own formula and repair and maintenance requirements. Before using any type of RV roof coating it is best to consult your RV’s manual to determine what type of roof you have and how to take care of it.

How to Maintain EPDM Roofing

EPDM roof if installed correctly

will not require a lot of maintenance in early years but over the period of

time EPDM roofs will require re-sealing of the seams and edges, but this is

typical roof maintenance regardless of the type of RV roof that you

choose. EPDM is low on maintenance but it does not react very well to

solvents and oil. That’s why it is important for you to keep your EPDM roof

clean and free from debris and oil residues.

How to Maintain TPO Roofing

TPO roofs are very durable and

their sturdy sheet installation is very popular among the RVers. Although TPO

roofing is a newer product than EPDM, but there is lot of information

available to maintain your TPO RV roofs. TPO roofs require more maintenance

than EPDM roofs because the seams require regular treatments with adhesive to

ensure proper sealing. The constant replacement of seams causes premature

deterioration on the TPO seams. However, with the increasing popularity of TPO

roofing many products are available which can enhance its longevity and to help

to combat premature deterioration on the TPO seams.

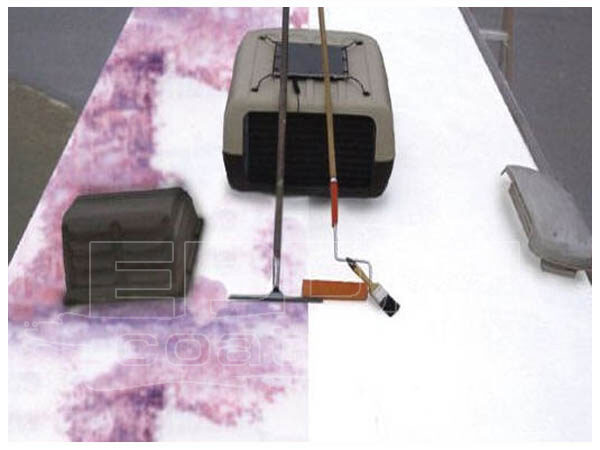

Liquid Roof Coatings

Liquid roofing the RV is gaining

popularity as it is easy to apply, durable and cost-effective too. liquid

roofing products like RV Liquid Roof coating creates a flexible seal around all

the fixtures and seams and adding strength to the caulking too. RV Liquid Roof

product is ideal choice for those who want a DIY product which is easy to

install as well as easy on maintenance. Handling of this product is quite easy

as compared to TPO and EPDM sheet roofing, which require much more time and an

assortment of tools that the average RVer might not have on hand.

Annual Cleaning and Inspections

Whether you prefer to choose RV

Liquid roof coatings or opt for some other roofing product, regular inspections

and annual cleaning is must to avoid damage. If your RV is not stored under

climate control conditions or it is exposed to extreme weather conditions more

frequent inspections may be a good idea.

You should clean the RV at least

twice a year with water and some good RV cleaner. Never use harsh chemical or

abrasive products as they can cause damage to the roof. Always use products

which are safe and compatible to use on the RV roof material otherwise, you

could do more harm than good.